Seals for GRP are commonly used in various industries for applications such as water distribution, sewage systems, oil and gas transportation, and industrial processes. Sealing GRP pipes effectively is essential to prevent leaks and maintain the integrity of the piping system. Here are some common types of seals used for GRP pipes:

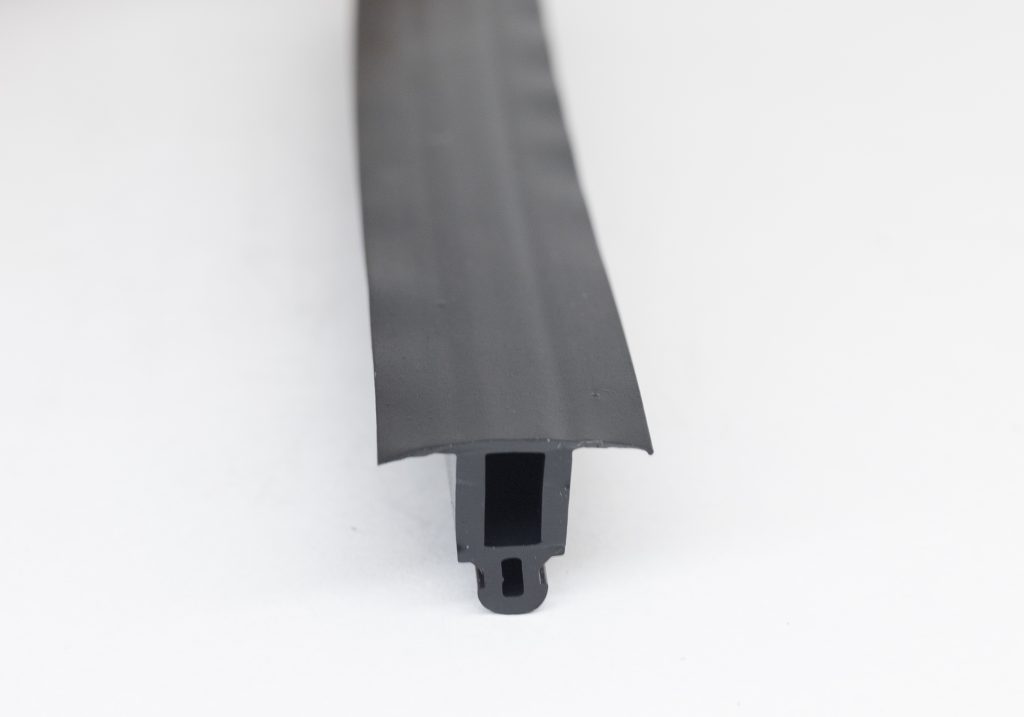

- Rubber Gaskets: Rubber gaskets are widely used for sealing GRP pipe joints. These gaskets are typically made of EPDM (Ethylene Propylene Diene Monomer) rubber or neoprene rubber and are installed in the pipe joints to create a watertight seal. The gaskets are compressed between the pipe spigot (male end) and the bell (female end) when the pipes are joined, forming a secure seal against leakage.

- Resin-Based Sealants: Resin-based sealants, such as epoxy resin or polyester resin, can be applied to GRP pipe joints to enhance their sealing effectiveness. These sealants are typically applied to the joint surfaces before assembly to fill any voids or irregularities and provide additional sealing protection against water infiltration.

- Adhesive Tapes: Adhesive tapes, such as butyl rubber tapes or waterproofing tapes, can be used to seal GRP pipe joints temporarily or as a secondary sealing measure. These tapes are applied to the joint surfaces before assembly and provide a flexible, waterproof barrier that helps prevent leaks.

- Threaded Connectors: Threaded connectors, such as threaded couplings or fittings, are used to join GRP pipes with threaded ends. Thread seal tape or pipe thread compound can be applied to the threaded ends of the pipes before assembly to create a tight seal and prevent leaks at the joints.

- Expansion Joint Seals: Expansion joint seals are used in GRP piping systems to accommodate thermal expansion and contraction of the pipes. These seals are typically made of flexible materials such as EPDM or silicone and are installed at expansion joints or transitions between different piping materials to prevent leaks and maintain the integrity of the system.

- Flange Gaskets: Flange gaskets are used in GRP piping systems with flanged connections to provide a seal between the flange faces of pipes and fittings. These gaskets come in various materials, including rubber, EPDM, PTFE (Polytetrafluoroethylene), and compressed non-asbestos, and are selected based on factors such as temperature, pressure, and chemical compatibility.

- Compression Couplings: Compression couplings are used to join GRP pipes without the need for solvent welding or threading. These couplings typically feature rubber or EPDM gaskets that create a tight seal when the coupling is tightened around the pipes, providing a secure and leak-proof connection.

When selecting sealing for GRP pipes, it’s essential to consider factors such as the pipe diameter, joint configuration, operating conditions (e.g., pressure, temperature), and the severity of the application environment to ensure proper sealing and long-term performance of the piping system. Additionally, proper installation practices and regular maintenance are critical for ensuring the effectiveness and durability of GRP pipe seals.