Concrete pipe seals play a critical role in various construction and infrastructure projects, particularly in the realm of drainage, sewage systems, and stormwater management. These seals are essential components that ensure the integrity, stability, and functionality of concrete pipes by preventing leakage, infiltration, and exfiltration of fluids, such as water and sewage. The following is an in-depth description of concrete pipe seals, their types, functions, materials, installation methods, and significance in construction projects:

1. Types of Concrete Pipe Seals:

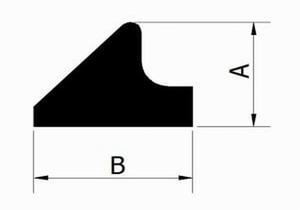

- Rubber Gaskets: These are the most common type of seals used in concrete pipes. They are made of high-quality rubber materials such as EPDM (ethylene propylene diene monomer), neoprene, or natural rubber. Rubber gaskets are designed to provide a flexible and watertight seal between pipe joints.

- Mastic Sealants: Mastic sealants are applied as a viscous compound to the pipe joint before connecting two concrete pipes. They provide an additional layer of protection against water infiltration and help to fill irregularities or gaps between pipe surfaces.

- Compression Seals: Compression seals consist of rubber or elastomeric materials that are compressed between the pipe joints using mechanical or hydraulic pressure. This compression creates a tight and durable seal that prevents leakage under high pressure or movement conditions.

2. Functions of Concrete Pipe Seals:

- Waterproofing: The primary function of concrete pipe seals is to waterproof the joints between concrete pipes, preventing the ingress of groundwater, surface water, or sewage into the pipe system.

- Structural Integrity: Seals help to maintain the structural integrity of the pipe network by reducing the risk of soil erosion, pipe displacement, or damage caused by water infiltration.

- Chemical Resistance: Some specialized seals offer resistance to chemicals present in sewage or industrial effluents, ensuring long-term durability and performance in harsh environments.

- Seismic Stability: Properly installed concrete pipe seals contribute to the seismic stability of underground infrastructure by minimizing the risk of joint failure or pipe separation during seismic events.

3. Materials Used in Concrete Pipe Seals:

- Rubber Compounds: EPDM, neoprene, and natural rubber are commonly used for manufacturing rubber gaskets due to their excellent flexibility, elasticity, and resistance to water and chemicals.

- Elastomers: Compression seals are typically made of synthetic elastomeric materials such as polyurethane or silicone, which offer superior compression set resistance and resilience.

- Mastic Compounds: Mastic sealants are formulated from a blend of bitumen, polymers, fillers, and additives to achieve desired adhesion, flexibility, and waterproofing properties.

4. Installation Methods:

- Clean and Dry Surfaces: Before installing concrete pipe seals, the joint surfaces must be thoroughly cleaned and dried to remove any debris, dirt, or moisture that could compromise the seal.

- Proper Alignment: It’s crucial to ensure proper alignment and fit between the concrete pipes before inserting the seal. Misalignment or unevenness can lead to premature failure of the seal.

- Appropriate Compression: For compression seals, the correct amount of compression force must be applied to achieve the desired seal tightness without over-compressing or damaging the seal.

- Sealant Application: Mastic sealants should be applied evenly and generously to the joint surfaces to ensure complete coverage and adhesion. Excess sealant should be trimmed or removed to maintain a neat finish.

5. Significance in Construction Projects:

- Long-Term Performance: High-quality concrete pipe seals contribute to the long-term performance and reliability of underground drainage and sewage systems, minimizing the need for maintenance and repairs.

- Environmental Protection: Properly sealed concrete pipes help to prevent pollution and environmental contamination by containing sewage, wastewater, and hazardous substances within the pipe network.

- Cost Savings: Investing in durable seals can lead to significant cost savings over the lifespan of the infrastructure, as it reduces the likelihood of water damage, pipe failures, and associated repair expenses.

- Compliance and Safety: Compliance with regulatory standards and codes regarding water quality, environmental protection, and public health is facilitated by using reliable concrete pipe seals that meet or exceed industry specifications.

Concrete pipe gaskets are indispensable components of underground infrastructure systems, ensuring watertightness, structural integrity, and environmental compliance in drainage, sewage, and stormwater management applications. By understanding the types, functions, materials, installation methods, and significance of concrete pipe seals, construction professionals can make informed decisions to enhance the performance and longevity of their projects.