Dilatation seals, also known as expansion joints or expansion seals, are specialized components used in construction, infrastructure, and engineering applications to accommodate movement, vibration, and thermal expansion or contraction within structures, buildings, pipelines, bridges, and other engineered systems. These seals are designed to provide flexible connections between adjacent structural elements or components while maintaining continuity, integrity, and functionality, even under dynamic or environmental conditions.

Here’s a comprehensive description of dilatation seals:

- Functionality: Dilatation seals serve multiple functions within built environments and infrastructure systems, including:

- Absorbing movement: Dilatation seals accommodate structural movement caused by factors such as thermal expansion and contraction, seismic activity, settlement, wind loading, or dynamic forces.

- Sealing joints: Dilatation seals prevent the ingress of water, air, dust, or pollutants into building interiors, substructures, or enclosed spaces, maintaining indoor air quality, comfort, and environmental integrity.

- Reducing noise and vibration: Dilatation seals attenuate noise transmission and dampen vibrations generated by mechanical equipment, traffic, or environmental sources, enhancing occupant comfort, safety, and productivity.

- Protecting structural integrity: Dilatation seals protect structural elements, building components, and infrastructure systems from damage, deterioration, or failure caused by movement, corrosion, weathering, or external forces.

- Types of Dilatation Seals:

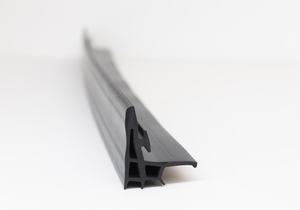

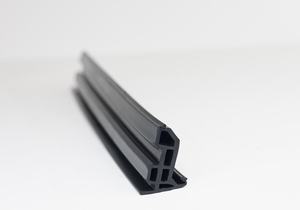

- Movement Joints: Movement joints, also known as expansion joints, are designed to accommodate horizontal, vertical, or multidirectional movement between adjacent structural elements such as floors, walls, facades, or bridge decks. They can be installed as surface-mounted, flush-mounted, or concealed joints, depending on aesthetic and functional requirements.

- Bridge Expansion Joints: Bridge expansion joints are specialized dilatation seals used in bridge decks, viaducts, or elevated roadways to accommodate thermal expansion and contraction, seismic movement, and dynamic loading. These joints may be modular, strip, or finger-type designs, incorporating elastomeric, metal, or hybrid materials to withstand heavy traffic loads and environmental exposure.

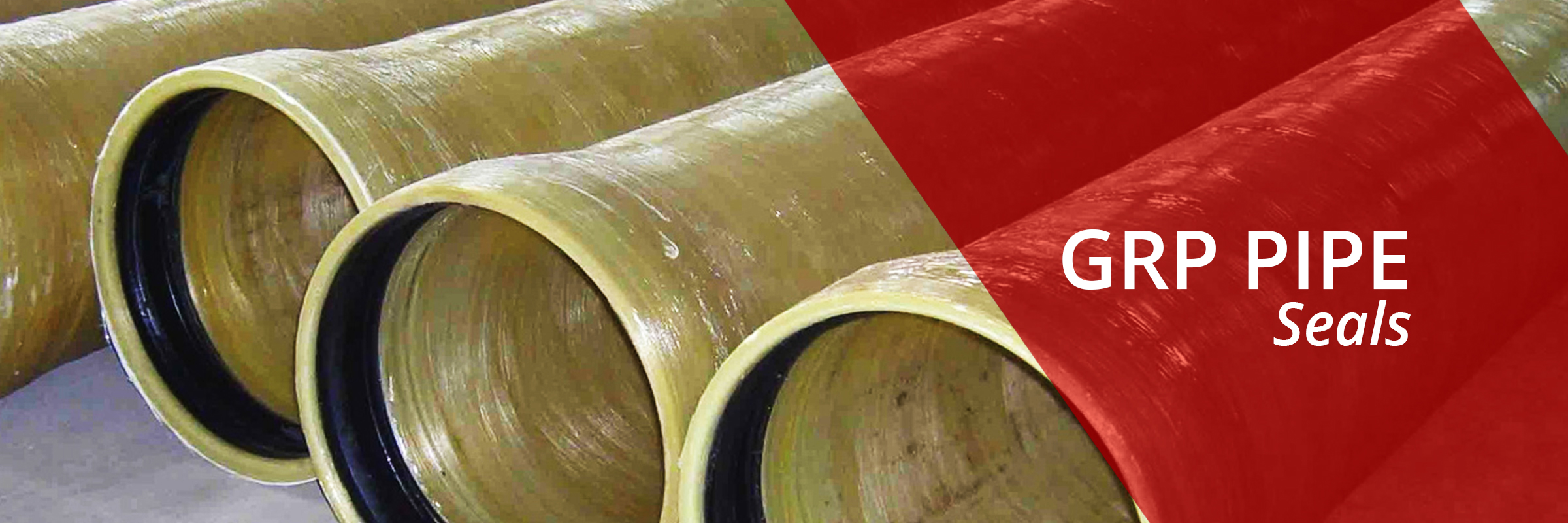

- Pipe Expansion Joints: Pipe expansion joints are employed in piping systems, ductwork, or conduits to absorb thermal expansion and contraction, vibration, or movement between pipe sections or components. They may be flexible bellows, slip-type, or expansion loop designs, constructed from elastomeric, metallic, or composite materials suitable for specific fluid, pressure, or temperature conditions.

- Wall and Floor Seals: Wall and floor seals are used in building envelopes, facades, curtain walls, or flooring systems to accommodate movement between building elements and substrates. They may include surface-mounted, recessed, or concealed profiles, incorporating elastomeric, silicone, or hybrid materials to ensure durability, weather resistance, and aesthetic compatibility.

- Railway Expansion Joints: Railway expansion joints are installed in rail tracks, platforms, or railway bridges to absorb track movement, thermal expansion, and dynamic loads induced by trains. These joints may feature modular, strip, or slab designs, incorporating rubber, steel, or composite materials to provide smooth ride quality, track stability, and safety for railway operations.

- Design Considerations: Dilatation seals are engineered to meet specific design criteria, performance requirements, and environmental conditions, including:

- Movement capacity: Dilatation seals are designed to accommodate anticipated movement ranges, deflection angles, or displacements between adjacent elements or components without compromising structural integrity or functional performance.

- Sealing effectiveness: Dilatation seals are tested and certified to provide reliable and durable seals against water ingress, air leakage, dust infiltration, or pollutant migration, ensuring compliance with building codes, standards, and regulations.

- Load resistance: Dilatation seals are engineered to withstand static and dynamic loads, traffic loads, wind loads, seismic forces, or other external loads encountered in their intended applications, ensuring long-term durability and safety.

- Material compatibility: Dilatation seals are selected based on compatibility with surrounding materials, substrates, coatings, or finishes to prevent chemical reactions, galvanic corrosion, or aesthetic discrepancies that could compromise performance or appearance.

- Aesthetic integration: Dilatation seals are available in various colors, finishes, textures, and profiles to complement architectural designs, finishes, or structural elements, ensuring visual continuity, coherence, and harmony within built environments.

- Installation and Maintenance: Dilatation seals are installed by qualified contractors, installers, or technicians using specialized tools, equipment, and techniques appropriate for each seal type and application. Proper installation practices ensure correct alignment, anchoring, fastening, and sealing of dilatation seals to achieve optimal performance and longevity. Regular inspection, cleaning, and maintenance of dilatation seals are recommended to detect signs of wear, damage, or degradation and to prevent premature failure or malfunction.

- Applications: Dilatation seals find widespread applications across various industries and sectors, including:

- Building construction: Dilatation seals are used in commercial buildings, residential developments, institutional facilities, and industrial complexes to accommodate movement in floors, walls, ceilings, facades, and roofs.

- Infrastructure projects: Dilatation seals are employed in bridges, highways, tunnels, railways, airports, ports, and public utilities to accommodate movement in expansion joints, bridge decks, viaducts, pavements, and pipelines.

- Mechanical systems: Dilatation seals are utilized in HVAC (heating, ventilation, and air conditioning), plumbing, electrical, and mechanical systems to absorb movement, vibration, or thermal expansion in pipes, ducts, conduits, and equipment.

- Specialty applications: Dilatation seals are deployed in specialized environments such as cleanrooms, laboratories, pharmaceutical facilities, food processing plants, and semiconductor manufacturing facilities to maintain cleanliness, hygiene, and contamination control while accommodating movement in structural elements or systems.

Dilatation gaskets play a crucial role in modern construction, infrastructure, and engineering projects by providing flexible, reliable, and durable solutions for accommodating movement, sealing joints, reducing noise and vibration, and protecting structural integrity. Their versatility, performance, and compatibility with diverse applications make them indispensable components in ensuring safety, functionality, and sustainability in built environments and infrastructure systems.